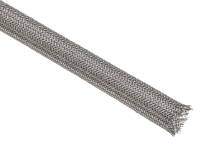

Braided Metal Cable Sleeving

Added Shielding & Microbial, RFI / EMI / ESD Protection

Additional Information

Braided Metal Sleeving offers cut and abrasion resistant options that are ideal for a wide variety of uses including grounding solutions, high-intensity weather, and temperature resistance. Metal sleeving is extremely durable and has EFI, RFI, ESD, and UV resistant options as well as antimicrobial and germicidal options. Metal cable sleeves are uniquely functional, flexible, durable and aesthetically pleasing making them perfect for many automotive, aerospace and outdoor applications. With virtually indestructible options like braided stainsless steel sleeves even your most vulnerable wires, cables and hoses will be safely tucked away while your project remains aesthetically stunning and rust free.

Braided metal cable sleeves, also known as braided metal sleeving, are a popular and versatile solution for organizing and protecting cables and wires in a wide range of applications. These sleeves are made of braided strands of metal, typically stainless steel or aluminum, and offer a number of benefits over traditional cable management solutions. One common use for braided metal cable sleeves is in the automotive industry. These sleeves are often used to protect wires and cables in vehicles, including wiring harnesses, fuel lines, and brake lines. The braided metal construction provides a high level of durability and resistance to abrasion, making them ideal for use in harsh automotive environments. In addition, the braided design allows for easy installation and flexibility, allowing the sleeves to be easily routed through tight spaces and around corners. Braided metal cable sleeves are also commonly used in the electronics and telecommunications industries. These sleeves are often used to protect and organize cables and wires in electronic devices, such as computers, smartphones, and tablets. The braided metal construction provides a high level of shielding against electromagnetic interference (EMI), making them ideal for use in electronic devices that are sensitive to EMI. In addition, the braided design allows for easy installation and flexibility, making them ideal for use in tight spaces and complex cable management systems. Another common use for braided metal cable sleeves is in the aerospace and aviation industries. These sleeves are often used to protect and organize cables and wires in aircraft, including wiring harnesses, fuel lines, and hydraulic lines. The braided metal construction provides a high level of durability and resistance to abrasion, making them ideal for use in harsh aerospace environments. In addition, the braided design allows for easy installation and flexibility, allowing the sleeves to be easily routed through tight spaces and around corners. In addition to these specific applications, braided metal cable sleeves are also commonly used in a wide range of other industries, including manufacturing, energy, and construction. These sleeves are often used to protect and organize cables and wires in a variety of settings, including factories, power plants, and construction sites.