ESD and Anti Static Mats for Electrical Safety

These mats safely dissipate or absorb the built-up static electricity

Additional Information

ESD and Anti Static Mats for Electrical Safety

In environments where static electricity poses a risk to sensitive electrical equipment and personnel safety, the use of ESD (Electrostatic Discharge) and anti-static mats is crucial. These specialized mats provide an effective solution to control and dissipate static charges, ensuring both equipment protection and a safe working environment. Let's delve into the various uses, features, and benefits of ESD and anti-static mats in electrical safety.

Uses:

-

Electronics Manufacturing: ESD and anti-static mats are widely utilized in electronics manufacturing facilities to protect delicate electronic components from harmful electrostatic discharge (ESD). These mats provide a controlled grounding path to prevent static charges from damaging sensitive equipment.

-

Testing and Repairs: Workstations or areas where electrical testing, repairs, or assembly of electronic devices take place can benefit from ESD and anti-static mats. These mats create a safe working environment by dissipating static charges and minimizing the risk of damage during handling or testing.

-

Server Rooms and Data Centers: ESD and anti-static mats play a vital role in server rooms and data centers where sensitive electronic equipment and servers are located. They help prevent static charges from damaging critical components and causing data loss or system failure.

-

Laboratories: Research laboratories working with electrical instruments or sensitive electronic devices rely on ESD and anti-static mats to maintain a static-free environment. These mats safeguard the accuracy and reliability of experimental data.

-

Cleanrooms: In cleanroom environments, ESD and anti-static mats are essential to prevent electrostatic discharge that could contaminate or compromise sensitive products or materials.

Features:

-

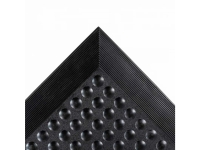

Conductive or Dissipative Materials: ESD and anti-static mats are typically made from conductive or dissipative materials, such as rubber or vinyl infused with carbon or other conductive additives. These materials effectively dissipate static charges and prevent the buildup of electrostatic potentials.

-

Grounding Capability: These mats provide a safe grounding path to channel static charges away from equipment or individuals. They often feature built-in grounding snaps or connectors for easy connection to grounding systems.

-

Surface Resistance: ESD and anti-static mats are engineered with specific surface resistance properties, measured in Ohms, to ensure proper dissipation of static charges. The mats' surface resistance should be within an optimal range to provide effective ESD protection.

-

Durability and Chemical Resistance: These mats are designed to withstand the demands of industrial environments and resist common workplace chemicals, ensuring long-lasting performance and protection.

-

Size and Customization Options: ESD and anti-static mats are available in various sizes to accommodate different workstations and areas. Some mats can be customized to fit specific requirements or integrated into larger workspaces seamlessly.

Benefits:

-

Equipment Protection: The primary benefit of ESD and anti-static mats is their ability to protect sensitive electrical equipment from potentially damaging electrostatic discharge. They prevent static charges from accumulating and discharging onto components, reducing the risk of equipment failure or costly repairs.

-

Personnel Safety: These mats significantly reduce the chance of personnel experiencing static shocks, which can be uncomfortable and potentially hazardous, improving overall safety in the workplace.

-

Enhanced Productivity: By providing a static-free working environment, ESD and anti-static mats enable employees to work confidently and efficiently, without the worry of damaging equipment or encountering electrical hazards.

-

Reduction in Costs: These mats contribute to cost savings by preventing equipment damage, reducing the need