Kable Kontrol® Flame Retardant Expandable PET Braided Cable Sleeving

Expands or Contracts up to 50% | Available In Various Sizes & Lengths

0.0 / 5

Kable Kontrol® FR Expandable PET Braided Cable Sleeving Features

- CSA VW-1 Approved

- FMVSS 302 Approved

- VW-1 rated flammability

- UL Temperature Approved

- Material: Polyethylene Terephthalate (PET)

- High Quality & Easy To Install

- Resists Gasoline, chemicals & Cleaning Solvents

- Operating temperature: -94°F to 257°F (-70°C to 125°C)

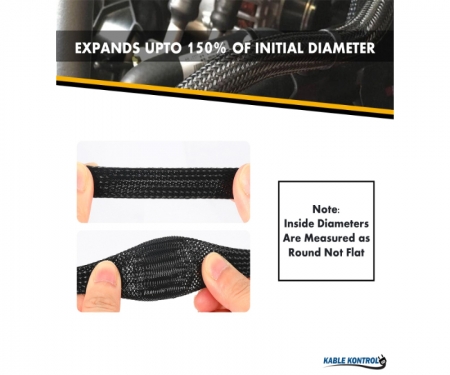

- Expands Up to 150% of Initial Diameter

- Cut & Abrasion Resistant

- High expansion ratio

- Excellent mechanical abrasion resistance

- Offers a high expansion ratio and excellent mechanical abrasion and cut resistance.

Kable Kontrol® Flame Retardant Expandable PET Braided Cable Sleeving, the ultimate solution for protecting and organizing your cables. Crafted & designed with high-quality, halogen-free, and flame retardant polyester, this cable sleeving ensures maximum safety and durability. With its VW-1 rated flammability and FMVSS 302 approval, you can trust it to resist gasoline, chemicals, and cleaning solvents, making it perfect for a variety of applications.

CSA VW-1 Approved: Meets strict flammability standards for enhanced safety. FMVSS 302 Approved: Complies with automotive flammability regulations, making it ideal for automotive wiring. UL Temperature Approved: Reliable performance across a wide temperature range from -94°F to 257°F (-70°C to 125°C). High Expansion Ratio: Expands up to 150% of its initial diameter, accommodating a wide range of cable sizes for easy installation. Resists Gasoline, Chemicals & Cleaning Solvents: Suitable for industrial and automotive applications where exposure to harsh chemicals and solvents is common. Economically Priced: Offers high-quality protection at an affordable price, without compromising on performance.

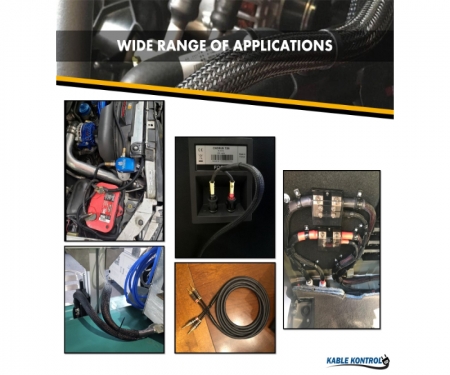

Versatile Applications:

- Automotive Wiring: Safeguard wiring harnesses in vehicles with resistance to gasoline and chemicals.

- Industrial Equipment: Protect cables in machinery and equipment exposed to harsh chemicals and solvents.

- Marine Applications: Ensure cable protection in marine environments with resistance to saltwater and fuel.

- Aerospace: Reliable cable protection in aircraft and spacecraft with high temperature and chemical resistance.

- Home Electronics: Manage and protect cables in home theaters, gaming systems, and computer setups.

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Expansion Range | Spool Put-Ups | ||

| Min. | Max. | Bulk | Shop | ||

| 1/8" | FRFW013 | 3/32" | 1/4" | 1,000' | 225' |

| 1/4" | FRFW025 | 1/8" | 7/16" | 1,000' | 200' |

| 3/8" | FRFW038 | 3/16” | 5/8” | 500' | 150' |

| 1/2" | FRFW050 | 1/4” | 3/4" | 500' | 100’ |

| 5/8" | FRFW058 | 3/8” | 1” | 250’ | 100’ |

| 3/4" | FRFW075 | 1/2” | 1 1/4” | 250’ | 100’ |

| 1" | FRFW100 | 5/8” | 1 5/8” | 250’ | 100’ |

| 1 1/4" | FRFW125 | 3/4” | 1 3/4” | 250’ | 100’ |

| 1 1/2" | FRFW150 | 1” | 2 1/2” | 200’ | 100’ |

| 1 3/4" | FRFW175 | 1 1/4” | 2 3/4” | 200’ | 100’ |

| 2" | FRFW200 | 1 3/4” | 3 1/2” | 200’ | 50’ |

| 2 1/2" | FR FW250 | 1 3/4” | 4 1/2” | 200’ | 50’ |

| 3" | FRFW300 | 2 1/2” | 4 3/4” | 100’ | 50’ |

*check for availability

| Physical Properties | |

| Monofilament Thickness (ASTM D-204) | .010 |

| Flammability Rating | UL-94 |

| Recommended Cutting | Hot Knife |

| Colors | 28 |

| Wall Thickness | .025 |

| Tensile Strength - Yarn (ASTM D-2265) lbs. | 7.5 |

| Abrasion Resistance | Medium |

| Specific Gravity | 1.38 |

| Moisture Absorption % (ASTM D-570) | .1 - .2 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | ||||

| Aromatic Solvents | 2 | |||

| Alipahtic Solvents | 1 | |||

| Chlorinated Solvents | 3 | |||

| Weak Bases | 1 | |||

| Strong Bases | 2 | |||

| Salt Water (O-S-1926) | 1 | |||

| Hydraulic Fluid (MIL-H-5606) | 1 | |||

| Lubricating Oil (MIL-A-8243) | 1 | |||

| De-Icing Fluid (MIL-A-8243) | 1 | |||

| Strong Acids | 3 | |||

| Strong Oxidants | 2 | |||

| Esters/Ketones | 1 | |||

| UV Light | 1 | |||

| Petroleum | 1 | |||

| Fungus (ASTM G-21) | 1 | |||

| Salts | 1 | |||

| Hard Vacuum Data (ASTM E-595 at 10-5 torr) | |

| TML | .19 |

| CVCM | .00 |

| WVR | .16 |

| Smoke D-Max (ASTM E-662) | 56 |

| Outgassing | Medium |

| Oxygen Index (ASTM D-2863) | 21 |

| Operating Temperatures | |

| Minimum Continuous | -94°F/-70°C |

| Maximum Continuous (MIL-I-23053) | 257°F/125°C |

| Melt (ASTM D-2117) | 482°F/250°C |

| Other Information | ||||

| Halogen Free | Yes | |||

| RoHS | Yes | |||

| SVHC | None | |||

| UL/CSA | Yes | |||

All Custom Cut Lengths 25’ – 50' Are

FINAL SALE: NON-CANCELLABLE & NON-REFUNDABLE

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

Kable Kontrol® Flame Retardant Expandable PET Braided Cable Sleeving, the ultimate solution for protecting and organizing your cables. Crafted & designed with high-quality, halogen-free, and flame retardant polyester, this cable sleeving ensures maximum safety and durability. With its VW-1 rated flammability and FMVSS 302 approval, you can trust it to resist gasoline, chemicals, and cleaning solvents, making it perfect for a variety of applications.

CSA VW-1 Approved: Meets strict flammability standards for enhanced safety. FMVSS 302 Approved: Complies with automotive flammability regulations, making it ideal for automotive wiring. UL Temperature Approved: Reliable performance across a wide temperature range from -94°F to 257°F (-70°C to 125°C). High Expansion Ratio: Expands up to 150% of its initial diameter, accommodating a wide range of cable sizes for easy installation. Resists Gasoline, Chemicals & Cleaning Solvents: Suitable for industrial and automotive applications where exposure to harsh chemicals and solvents is common. Economically Priced: Offers high-quality protection at an affordable price, without compromising on performance.

Versatile Applications:

- Automotive Wiring: Safeguard wiring harnesses in vehicles with resistance to gasoline and chemicals.

- Industrial Equipment: Protect cables in machinery and equipment exposed to harsh chemicals and solvents.

- Marine Applications: Ensure cable protection in marine environments with resistance to saltwater and fuel.

- Aerospace: Reliable cable protection in aircraft and spacecraft with high temperature and chemical resistance.

- Home Electronics: Manage and protect cables in home theaters, gaming systems, and computer setups.

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Expansion Range | Spool Put-Ups | ||

| Min. | Max. | Bulk | Shop | ||

| 1/8" | FRFW013 | 3/32" | 1/4" | 1,000' | 225' |

| 1/4" | FRFW025 | 1/8" | 7/16" | 1,000' | 200' |

| 3/8" | FRFW038 | 3/16” | 5/8” | 500' | 150' |

| 1/2" | FRFW050 | 1/4” | 3/4" | 500' | 100’ |

| 5/8" | FRFW058 | 3/8” | 1” | 250’ | 100’ |

| 3/4" | FRFW075 | 1/2” | 1 1/4” | 250’ | 100’ |

| 1" | FRFW100 | 5/8” | 1 5/8” | 250’ | 100’ |

| 1 1/4" | FRFW125 | 3/4” | 1 3/4” | 250’ | 100’ |

| 1 1/2" | FRFW150 | 1” | 2 1/2” | 200’ | 100’ |

| 1 3/4" | FRFW175 | 1 1/4” | 2 3/4” | 200’ | 100’ |

| 2" | FRFW200 | 1 3/4” | 3 1/2” | 200’ | 50’ |

| 2 1/2" | FR FW250 | 1 3/4” | 4 1/2” | 200’ | 50’ |

| 3" | FRFW300 | 2 1/2” | 4 3/4” | 100’ | 50’ |

*check for availability

| Physical Properties | |

| Monofilament Thickness (ASTM D-204) | .010 |

| Flammability Rating | UL-94 |

| Recommended Cutting | Hot Knife |

| Colors | 28 |

| Wall Thickness | .025 |

| Tensile Strength - Yarn (ASTM D-2265) lbs. | 7.5 |

| Abrasion Resistance | Medium |

| Specific Gravity | 1.38 |

| Moisture Absorption % (ASTM D-570) | .1 - .2 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | ||||

| Aromatic Solvents | 2 | |||

| Alipahtic Solvents | 1 | |||

| Chlorinated Solvents | 3 | |||

| Weak Bases | 1 | |||

| Strong Bases | 2 | |||

| Salt Water (O-S-1926) | 1 | |||

| Hydraulic Fluid (MIL-H-5606) | 1 | |||

| Lubricating Oil (MIL-A-8243) | 1 | |||

| De-Icing Fluid (MIL-A-8243) | 1 | |||

| Strong Acids | 3 | |||

| Strong Oxidants | 2 | |||

| Esters/Ketones | 1 | |||

| UV Light | 1 | |||

| Petroleum | 1 | |||

| Fungus (ASTM G-21) | 1 | |||

| Salts | 1 | |||

| Hard Vacuum Data (ASTM E-595 at 10-5 torr) | |

| TML | .19 |

| CVCM | .00 |

| WVR | .16 |

| Smoke D-Max (ASTM E-662) | 56 |

| Outgassing | Medium |

| Oxygen Index (ASTM D-2863) | 21 |

| Operating Temperatures | |

| Minimum Continuous | -94°F/-70°C |

| Maximum Continuous (MIL-I-23053) | 257°F/125°C |

| Melt (ASTM D-2117) | 482°F/250°C |

| Other Information | ||||

| Halogen Free | Yes | |||

| RoHS | Yes | |||

| SVHC | None | |||

| UL/CSA | Yes | |||

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Videos

All Custom Cut Lengths 25’ – 50' Are

FINAL SALE: NON-CANCELLABLE & NON-REFUNDABLE