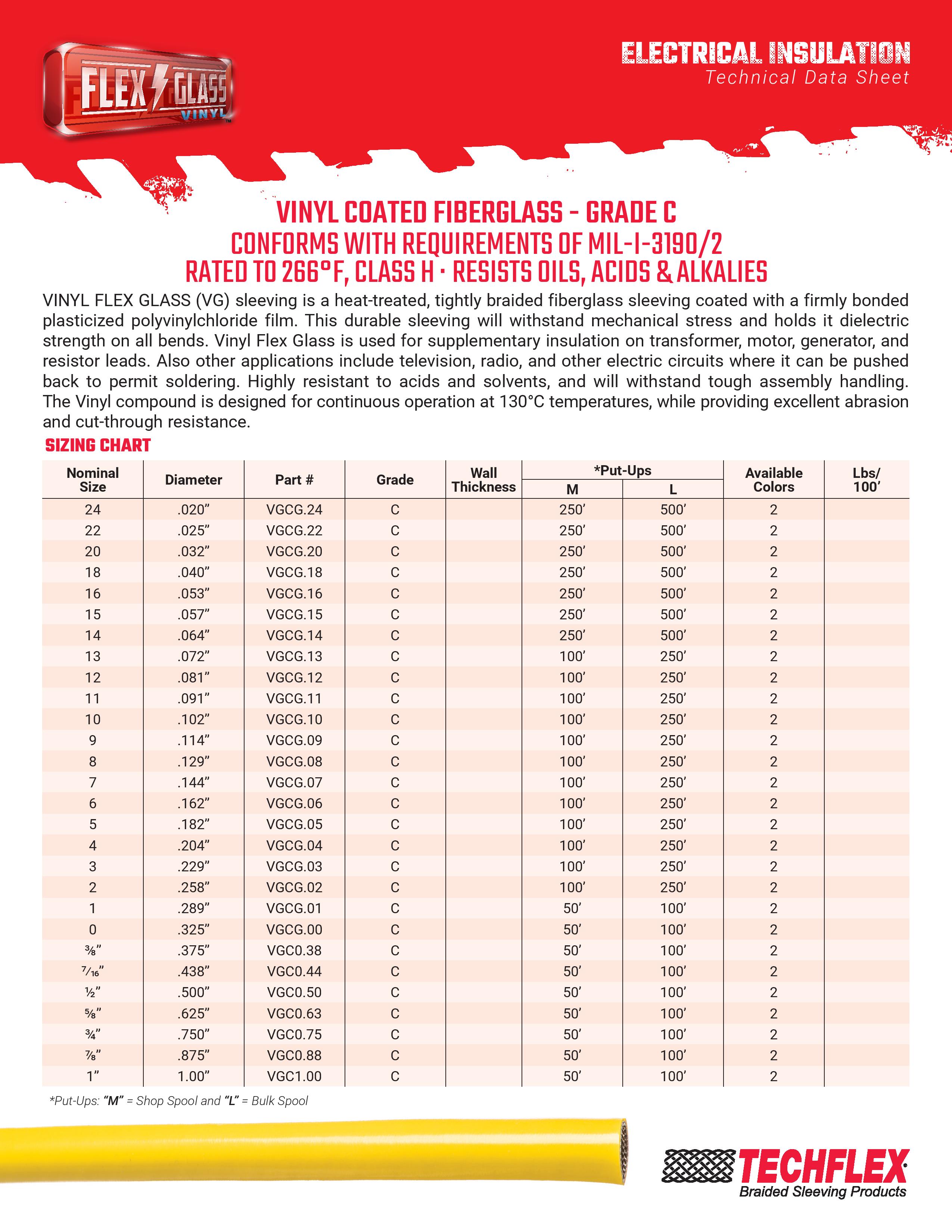

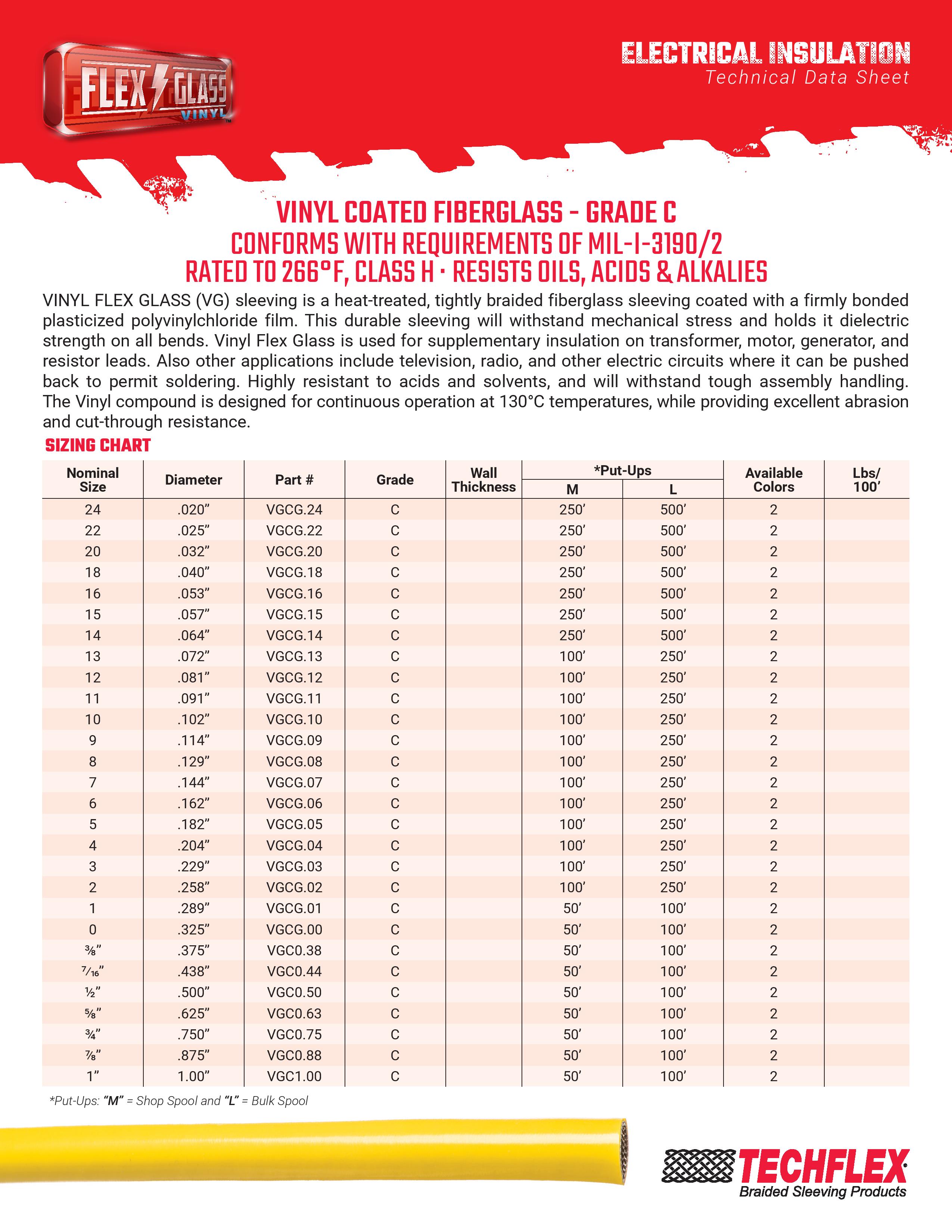

Techflex® Flexglass Electrical Insulation Sleeving - Vinyl Coated - Grade C

(2500 Volts) - Rated Up to 266°F | MIL-I-3190/3 | VW-1 Certified

0.0 / 5

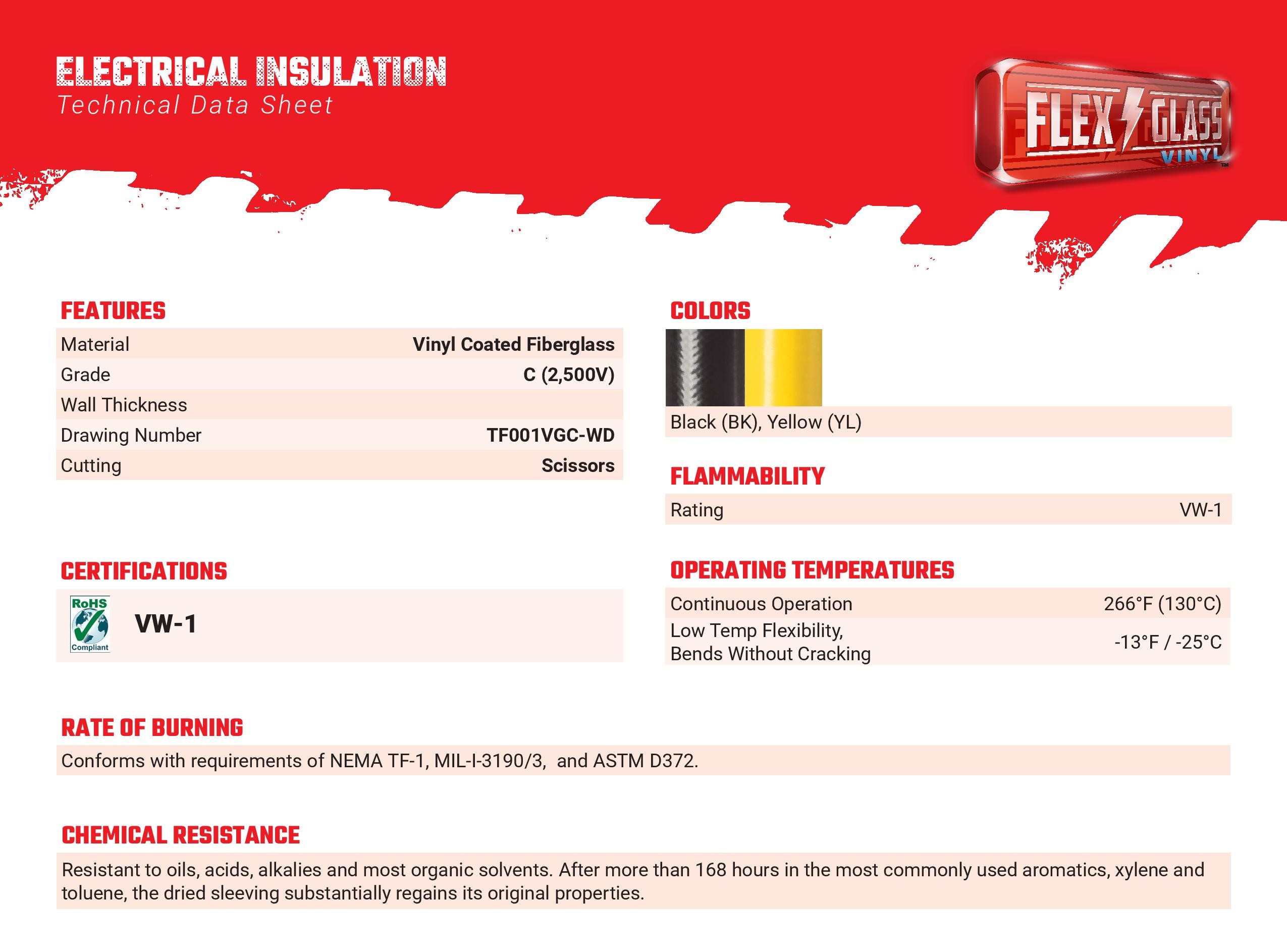

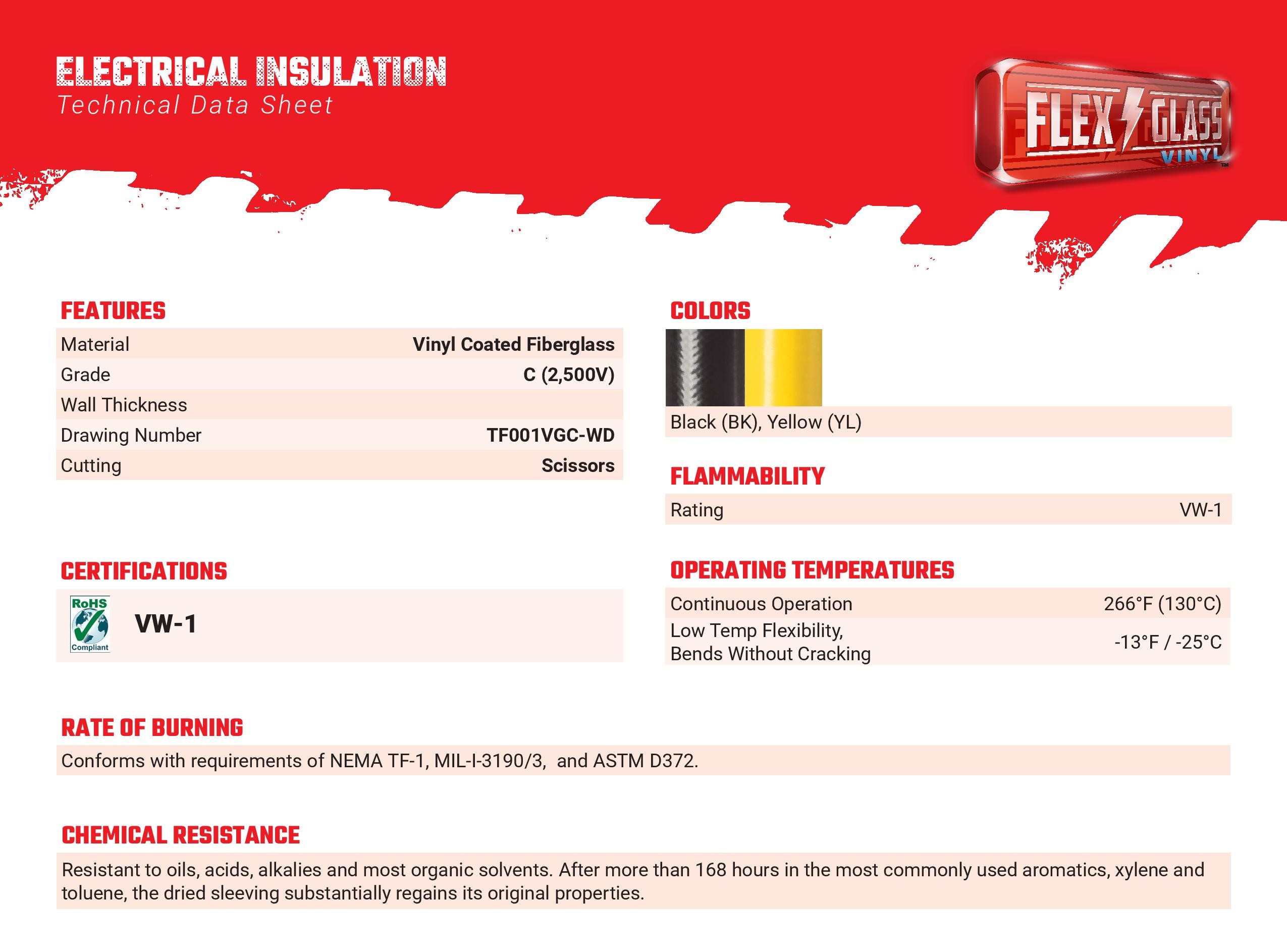

Vinyl Flexglass Sleeving - Grade C Features

- Material: Fiberglass with PVC coating.

- Durability: Withstands mechanical stress.

- Dielectric Strength: Maintains insulation on bends.

- Applications: Suitable for various electrical components.

- Chemical Resistance: Resistant to oils, acids, and solvents.

- Temperature Rating: Operates at up to 130°C.

- Abrasion Resistance: Excellent durability.

- Burn Rate: Conforms with requirements of NEMA TF-1, MIL-I-3190/3, and ASTM D372.

- Chemical Resistance: Withstands exposure to common solvents.

Techflex® Flexglass Electrical Insulation Sleeving - Vinyl Coated - Grade C is a robust and versatile electrical insulation solution. This sleeving is crafted from a heat-treated, tightly braided fiberglass core, which is coated with a firmly bonded plasticized polyvinyl chloride (PVC) film. This combination of materials offers a range of exceptional features. The durability of this sleeving is one of its standout attributes. It can withstand mechanical stress, ensuring longevity in various applications. Even when bent, it maintains its dielectric strength, guaranteeing reliable electrical insulation for sensitive components. This product finds extensive utility in the electrical industry, where supplementary insulation is crucial. It is commonly used to protect transformer, motor, generator, and resistor leads. Furthermore, it is well-suited for applications in television, radio, and other electric circuits, where it can be conveniently pushed back to allow for soldering.

Chemical resistance is another remarkable feature. This sleeving is highly resistant to oils, acids, alkalies, and most organic solvents. It can endure exposure to harsh environmental conditions, making it a reliable choice for demanding applications. The vinyl compound used in the coating is engineered to operate continuously at temperatures of up to 130°C, ensuring it can handle a wide range of operating conditions. Additionally, it offers excellent abrasion and cut-through resistance, safeguarding the components it encases. In terms of safety, this product complies with the rate of burning requirements set by NEMA TF-1, MIL-I-3190/3, and ASTM D372, making it a trustworthy choice for applications where fire safety is a concern. Lastly, the chemical resistance of this product is further demonstrated by its ability to withstand exposure to common aromatics such as xylene and toluene. Even after more than 168 hours of exposure, the sleeving substantially regains its original properties, showcasing its resilience in challenging environments.

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

Techflex® Flexglass Electrical Insulation Sleeving - Vinyl Coated - Grade C is a robust and versatile electrical insulation solution. This sleeving is crafted from a heat-treated, tightly braided fiberglass core, which is coated with a firmly bonded plasticized polyvinyl chloride (PVC) film. This combination of materials offers a range of exceptional features. The durability of this sleeving is one of its standout attributes. It can withstand mechanical stress, ensuring longevity in various applications. Even when bent, it maintains its dielectric strength, guaranteeing reliable electrical insulation for sensitive components. This product finds extensive utility in the electrical industry, where supplementary insulation is crucial. It is commonly used to protect transformer, motor, generator, and resistor leads. Furthermore, it is well-suited for applications in television, radio, and other electric circuits, where it can be conveniently pushed back to allow for soldering.

Chemical resistance is another remarkable feature. This sleeving is highly resistant to oils, acids, alkalies, and most organic solvents. It can endure exposure to harsh environmental conditions, making it a reliable choice for demanding applications. The vinyl compound used in the coating is engineered to operate continuously at temperatures of up to 130°C, ensuring it can handle a wide range of operating conditions. Additionally, it offers excellent abrasion and cut-through resistance, safeguarding the components it encases. In terms of safety, this product complies with the rate of burning requirements set by NEMA TF-1, MIL-I-3190/3, and ASTM D372, making it a trustworthy choice for applications where fire safety is a concern. Lastly, the chemical resistance of this product is further demonstrated by its ability to withstand exposure to common aromatics such as xylene and toluene. Even after more than 168 hours of exposure, the sleeving substantially regains its original properties, showcasing its resilience in challenging environments.

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.