Bulk Network Cable

1000 Ft Boxes - Bulk Cat 5E & Bulk Cat 6 Available In 8 Colors

0.0 / 5

Network Cable Bulk Cat5E & Bulk Cat6 Cable Features

- SOLD IN BOXES CONTAINING 1000 ft LENGTH

- Square: 24AWG

- Cat5E 350 Mhz

- Cat6 550 Mhz

- PVC Jacket

- 8 Conductor/4 Pair

- Solid Copper Conductor

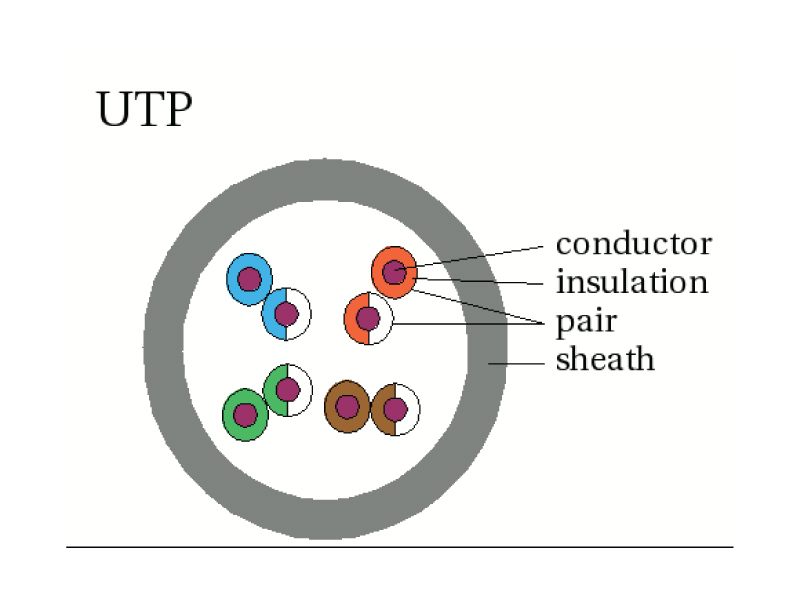

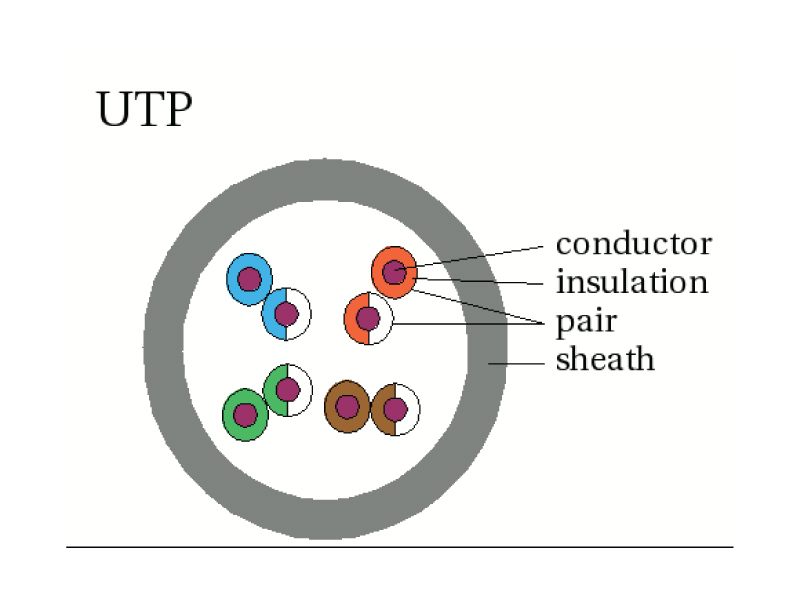

- UTP (Unshielded Twisted Pair)

- Sequential Foot Markers

- Verified Compliant with EIA/TIA

Available in 1,000-foot bulk box, the high-density polyethylene-insulated cable is perfect for Network, Voice, and Multimedia. Featuring four-pair unshielded twisted pair cable and 24AWG solid bare copper conductors, the cable is foot marked and housed in an EZ pull box.

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

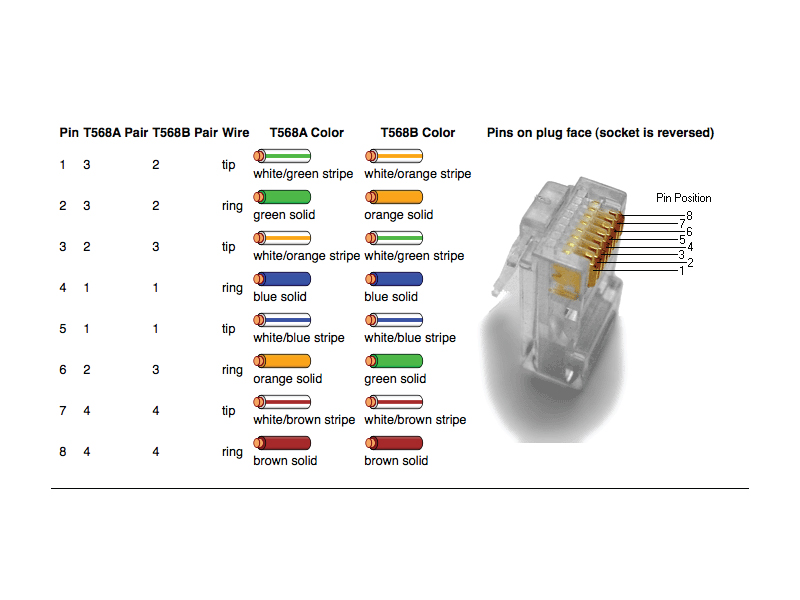

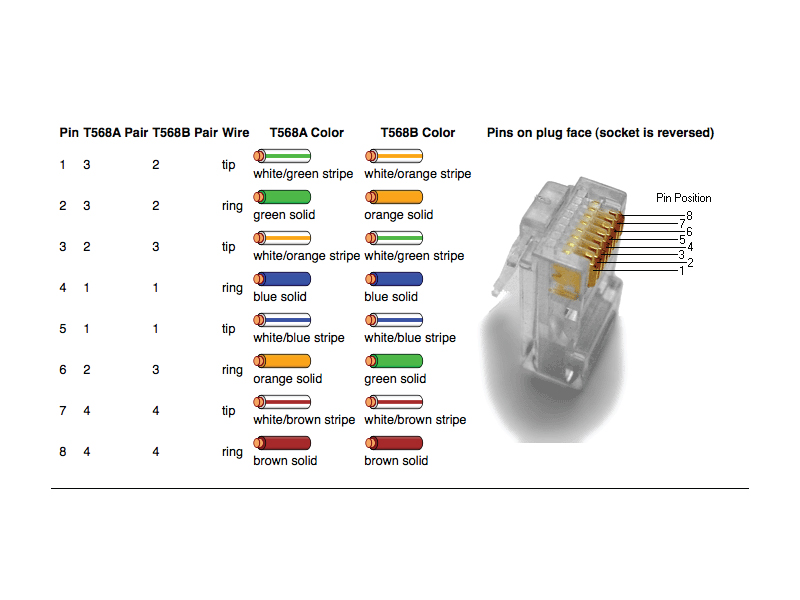

RJ45 Pin Out

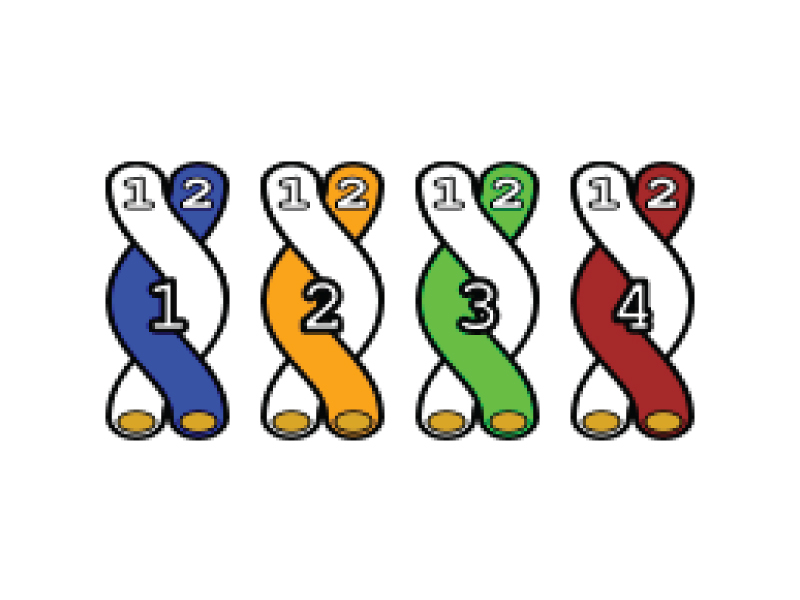

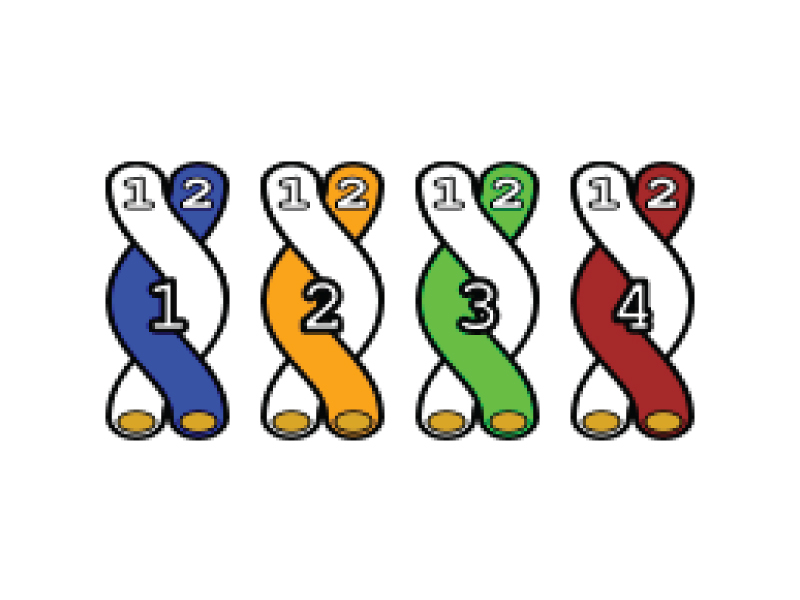

Colour Code

UDP Cable Structure

We have a 30-day return policy, which means you have 30 days after receiving your item to request a return.

To be eligible for a return, your item must be in the same condition that you received it, and in its original packaging. You’ll also need the receipt or proof of purchase.

To start a return, you can fill out the ORDER RETURN FORM HERE. If your return is accepted, we’ll send you the instructions on how and where to send your package. Items sent back to us without first requesting a return will not be accepted.

Damages and issues

Please inspect your order upon reception and contact us immediately if the item is defective, damaged or if you receive the wrong item, so that we can evaluate the issue and make it right.

Exceptions / non-returnable items

Certain types of items cannot be returned, like custom products (such as special orders or personalized items). Please get in touch if you have questions or concerns about your specific item. Certain Items will Carry restocking fees for us to take back into our stock, This is due to items being made to order or for being an oversized item.

Exchanges

The fastest way to ensure you get what you want is to return the item you have, and once the return is accepted, make a separate purchase for the new item.

Refunds

We will notify you once we’ve received and inspected your return, and let you know if the refund was approved or not. If approved, you’ll be automatically refunded on your original payment method. Please remember it can take some time for your bank or credit card company to process and post the refund too.

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

Available in 1,000-foot bulk box, the high-density polyethylene-insulated cable is perfect for Network, Voice, and Multimedia. Featuring four-pair unshielded twisted pair cable and 24AWG solid bare copper conductors, the cable is foot marked and housed in an EZ pull box.

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

RJ45 Pin Out

Colour Code

UDP Cable Structure

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Videos

We have a 30-day return policy, which means you have 30 days after receiving your item to request a return.

To be eligible for a return, your item must be in the same condition that you received it, and in its original packaging. You’ll also need the receipt or proof of purchase.

To start a return, you can fill out the ORDER RETURN FORM HERE. If your return is accepted, we’ll send you the instructions on how and where to send your package. Items sent back to us without first requesting a return will not be accepted.

Damages and issues

Please inspect your order upon reception and contact us immediately if the item is defective, damaged or if you receive the wrong item, so that we can evaluate the issue and make it right.

Exceptions / non-returnable items

Certain types of items cannot be returned, like custom products (such as special orders or personalized items). Please get in touch if you have questions or concerns about your specific item. Certain Items will Carry restocking fees for us to take back into our stock, This is due to items being made to order or for being an oversized item.

Exchanges

The fastest way to ensure you get what you want is to return the item you have, and once the return is accepted, make a separate purchase for the new item.

Refunds

We will notify you once we’ve received and inspected your return, and let you know if the refund was approved or not. If approved, you’ll be automatically refunded on your original payment method. Please remember it can take some time for your bank or credit card company to process and post the refund too.